Elfsquad CPQ for

Packaging and Production Lines Manufacturing

You're struggling with setting up complex systems, leading to mistakes and wasted resources. Poor collaboration causes communication issues and mismatched components. Inefficient use of space disrupts workflows and raises costs, while lack of visualization tools results in expensive errors and delays.

Optimized Resource Allocation:

Make sure every component in the production line fits the customer’s needs. Consider what each part needs, even within other parts. This cuts down on waste, boosts productivity, and makes the most of resources, saving money during production.

Improved Collaboration:

Improve communication among everyone involved in setting up complex production lines with one central platform for sharing ideas in real-time. Engineers, designers, sales teams, and clients can all give input, make smart choices, and ensure that nested machinery fits together smoothly. This builds trust and makes the process more efficient for everyone.

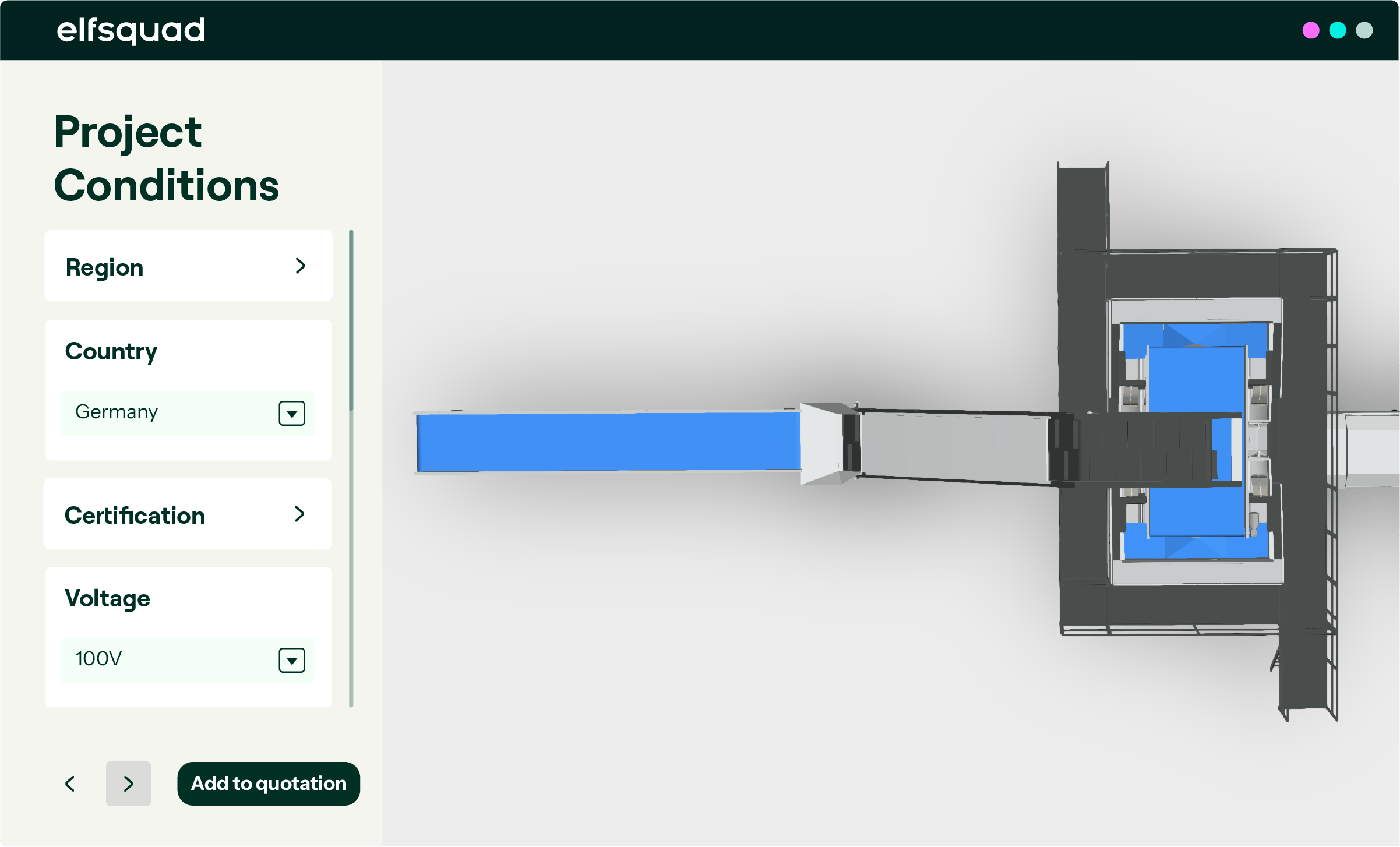

Optimized Floorspace Planning

Maximize efficiency and productivity by smartly arranging machinery, customizing layouts, and using visualization tools to prevent costly disruptions.

Floorspace Utilization

Elfsquad uses smart modeling to arrange machinery efficiently in the available space. This means you use every inch effectively without overcrowding. The result? Smoother workflows, better productivity, and lower costs because you're not wasting extra space.

Customized Layout Design

Customize production setups to fit exact needs and space limits. Arrange machinery and lines flexibly, keeping in mind things like workflow, accessibility, and safety rules. By matching the layout to each facility's unique needs, manufacturers can work more efficiently, cut downtime, and boost overall production.

Visualization and Analysis

Before making changes, see how different layout options would work. With 3D models and other visuals, manufacturers can see what the new layout would look like. They can spot any problems early and make smart choices to improve the layout. This way, they avoid expensive fixes or disruptions to production later on.

WSP Systems wipes Excel Sheets off the table and reduces price calculation time by 75%

It becomes a win-win situation: customers are served perfectly by the account managers and Inside Sales, while engineering can get to work immediately without any confusion throughout the trajectory.

Our Customers Are Scaling Up

Together, we’re reshaping the manufacturing landscape.